Polyester Conveyor Belt

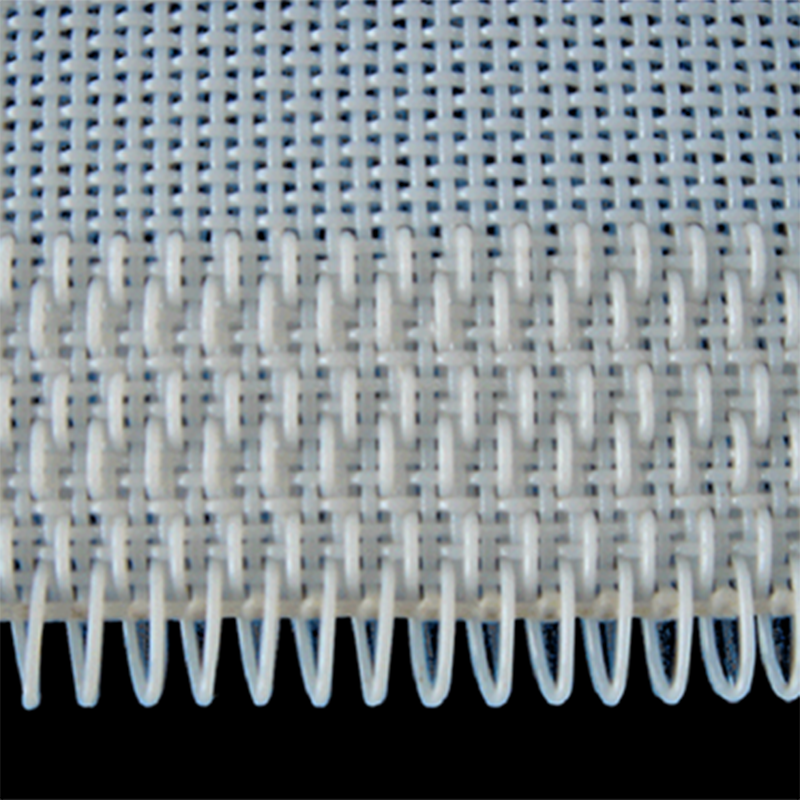

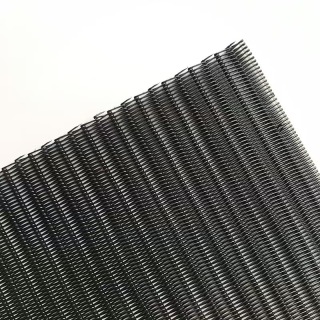

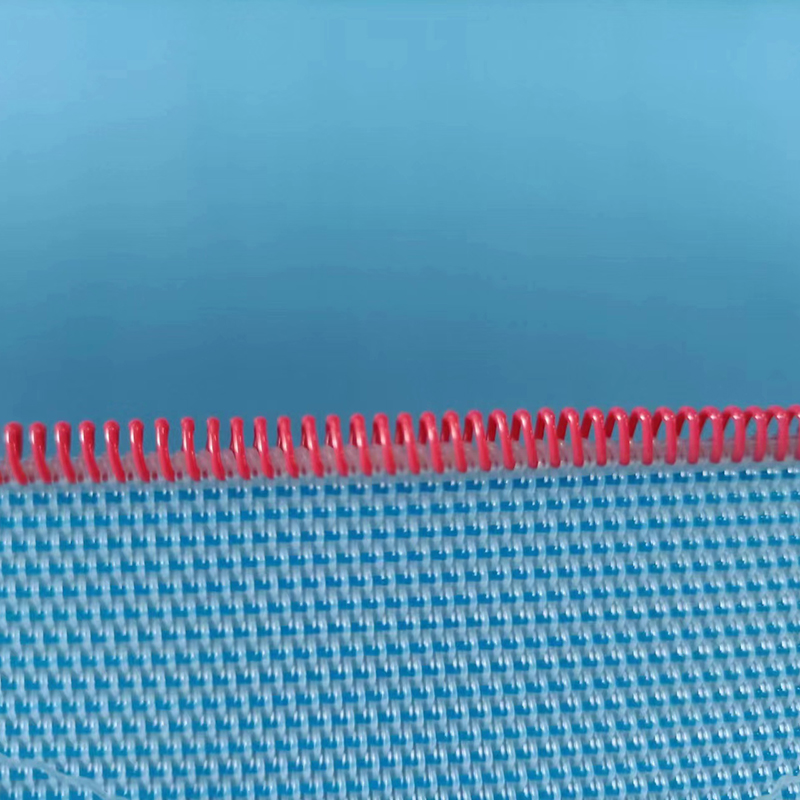

1. The Polyester Dryer Screen Dryer Belt we produce is connected by anti-hydrolysis polyester spiral ring, which is resistant to high temperature and moisture, and is suitable for complex environments.

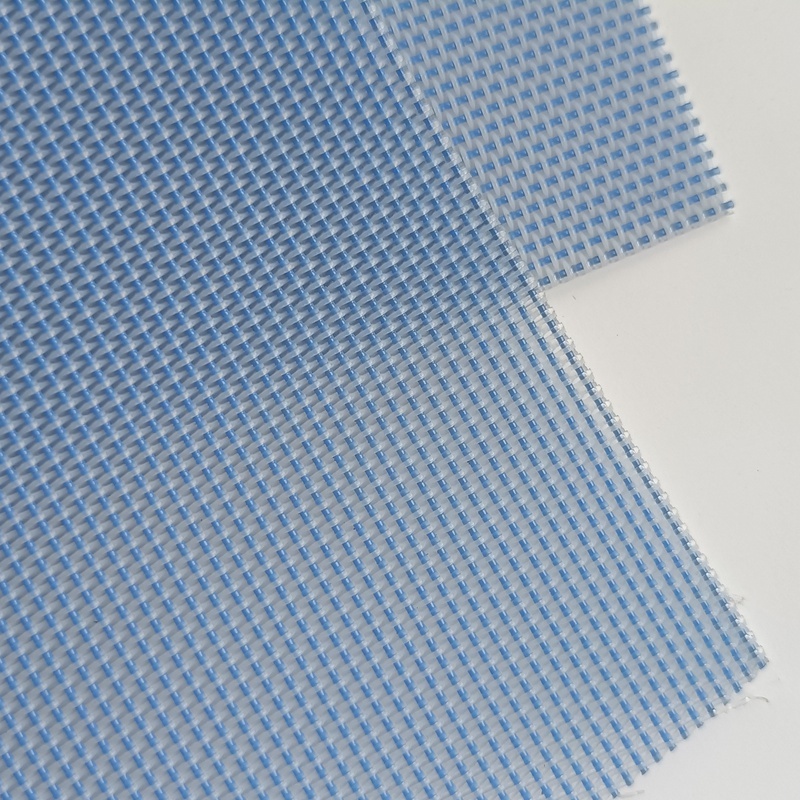

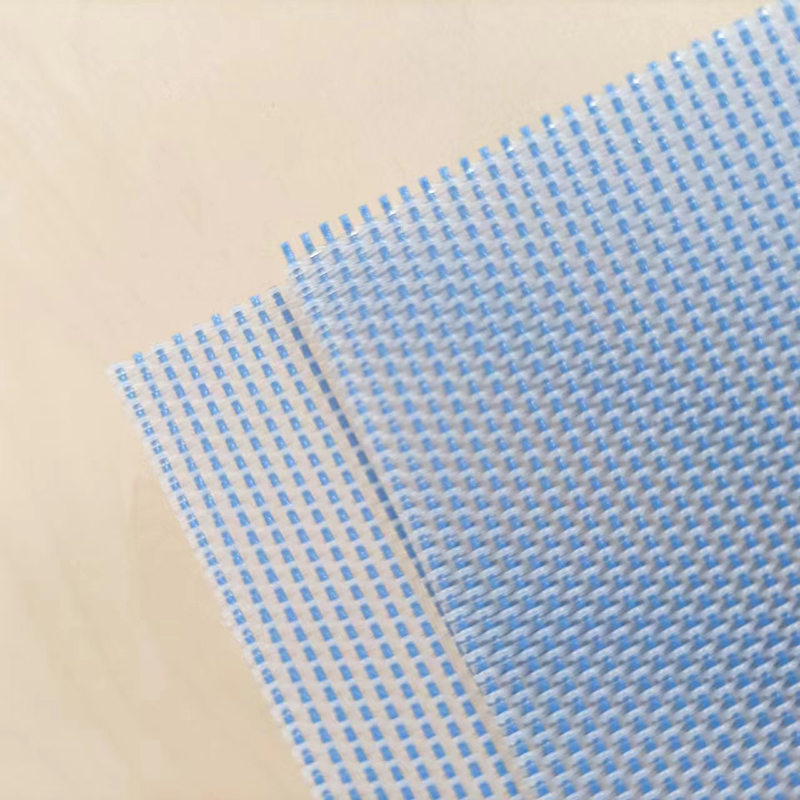

2. Our Polyester Spiral Conveyor Belt warp wire is soft and resistant to twists, and the weft wire is straight and wide, ensuring stable transportation without deformation and improving equipment operation efficiency.

3. The Polyester Spiral Dryer Fabric we produce is wear-resistant and corrosion-resistant, reducing replacement frequency, reducing maintenance costs, and improving production efficiency.

Product introduction of polyester spiral conveyor belt:

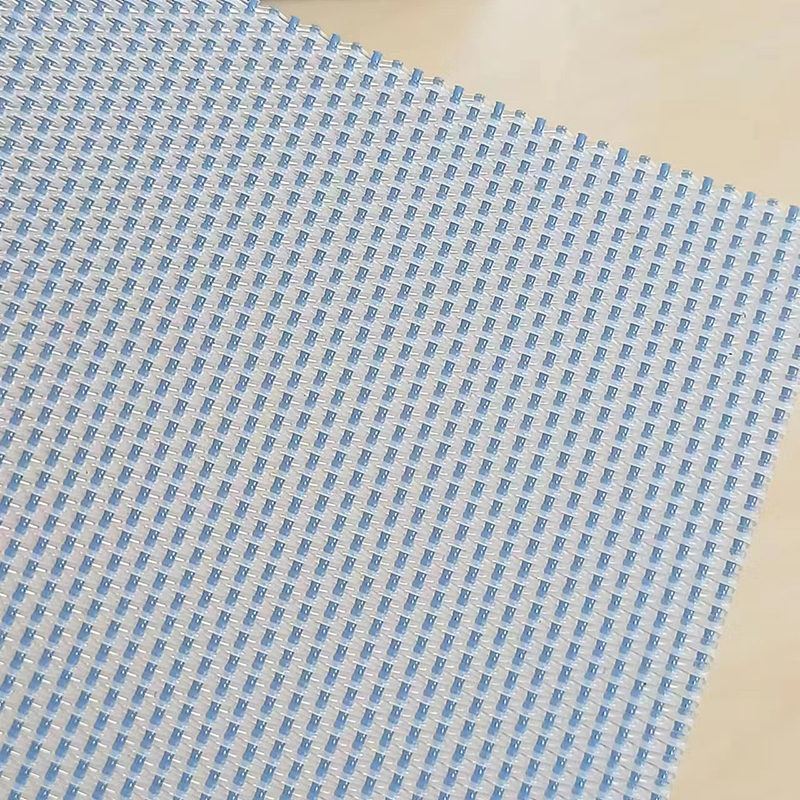

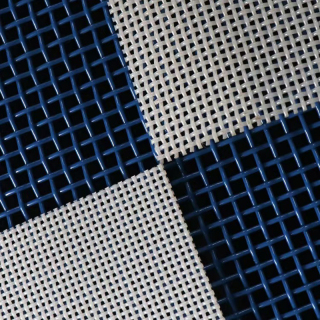

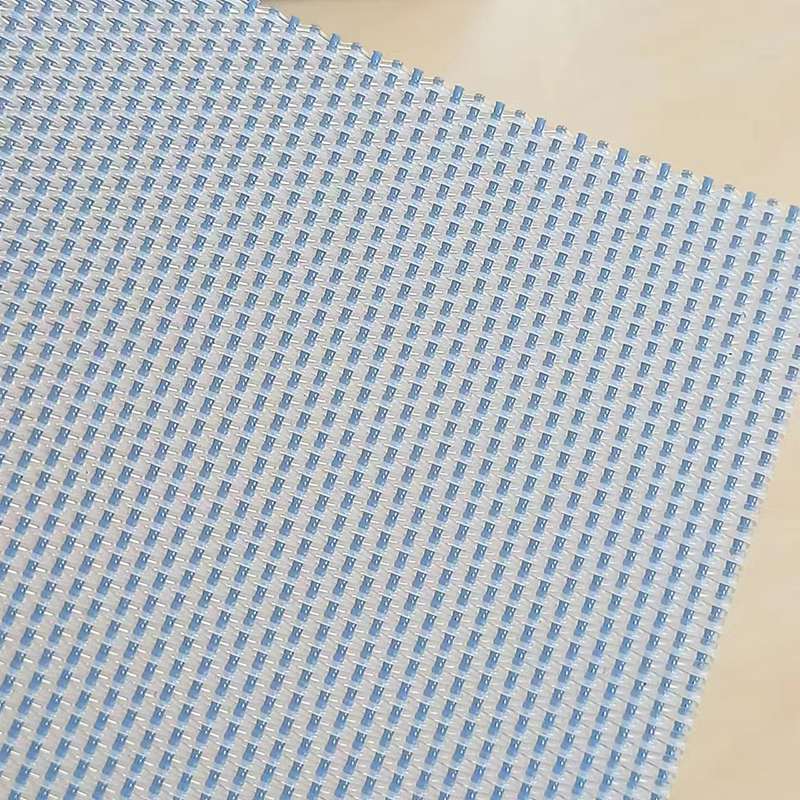

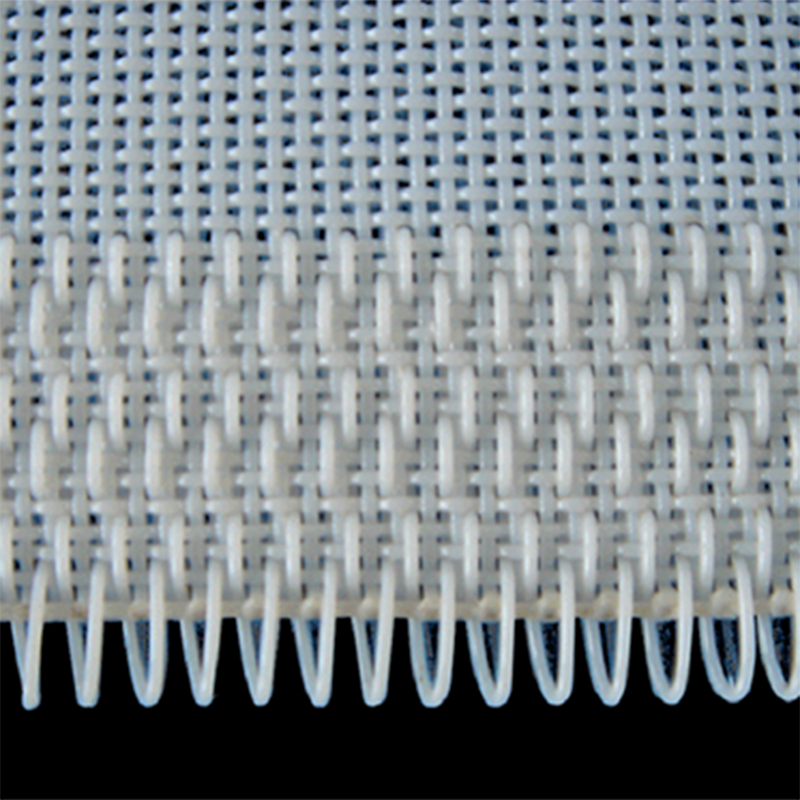

The polyester spiral conveyor belt we produce is a conveyor belt made of high-strength polyester and nylon materials, using a plain weave process and connected by a hydrolysis-resistant polyester spiral ring. Polyester spiral conveyor belt has a stable structure and excellent performance, and can be used for a variety of industrial conveying needs. With excellent high temperature resistance, wear resistance and hydrolysis resistance, polyester spiral conveyor belt can still maintain stable operation under high load and complex environment, and is widely used in conveying systems in food processing, textile printing and dyeing, wood processing, papermaking and other industries.

Product advantages of polyester spiral conveyor belt:

The polyester spiral conveyor belt we produce has good stability and ultra-long service life, and can maintain good performance in extreme environments such as high temperature and high humidity. The soft diameter of polyester spiral conveyor belt can provide excellent flexibility, ensuring that it is not easy to break during transportation, while the straight and wide weft enhances the support of the conveyor belt, so that it can still run smoothly at high speed. The hydrolysis-resistant polyester spiral ring connection method used in our polyester spiral dryer fabric improves the durability of polyester spiral conveyor belt and reduces the maintenance requirements during use.

Product application of polyester spiral dryer fabric:

The polyester spiral dryer fabric we produce is widely used in various industrial production conveying systems, especially in food processing, textile printing and dyeing, papermaking, wood processing, chemical production and other industries. In the food industry, it can be used for drying, cooling, cleaning and other links; in the textile and printing and dyeing industries, it can efficiently convey fabrics and keep them flat; in papermaking and wood processing, it can ensure uniform material transportation and improve production efficiency. With its excellent performance, this conveyor belt has become an ideal choice for stable transportation in many industries.

Product features of polyester spiral dryer fabric:

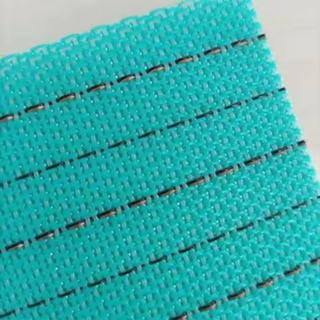

1. Polyester spiral dryer fabric is acid-resistant, alkali-resistant, wear-resistant and high-temperature resistant.

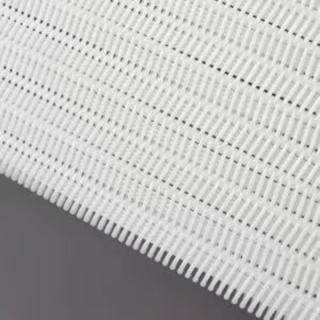

2. The polyester spiral dryer fabric mesh belt joints made of stainless steel are cut to suit the mesh belt and actual application occasions.

3. The special polyester material and weaving structure, the polyester papermaking mesh makes our mesh belt have a good surface effect, which is convenient for the unloading and regeneration of the mesh belt.

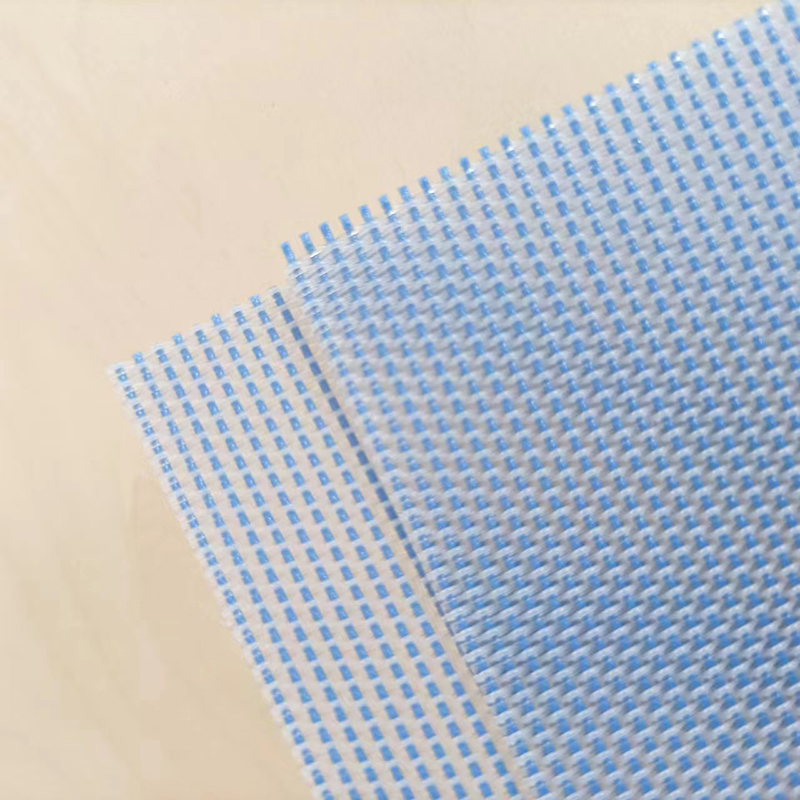

4. The polyester spiral dryer fabric has high tensile strength, strong wrinkle resistance, uniform mesh monofilament and flexibility.

5. The glued joints of the polyester dryer woven mesh screen filter belt are well-made, and the polyester papermaking mesh uses imported latex, which is not easy to fall off.

6. The surface of the polyester dryer woven mesh screen filter belt is smooth, the mud cake is easy to peel off, and the filter belt is easy to wash.

7. Polyester dryer woven mesh screen filter cake is thick, very easy to regenerate, and easy to peel off. It has stable shaping, no deformation, no deviation, no pleating, high tensile strength, and strong acid and alkali resistance.

8. The tension of polyester dryer woven mesh screen filter belt is generally controlled at 0.3-0.7MPa, and the common value is 0.5MPa. The filter belt travel speed is 1-7m/min.

Our services:

Due to the wide application field of polyester dryer woven mesh screen, different industries have different specifications and performance requirements for polyester dryer woven mesh screen. Our technical team can provide personalized selection suggestions and customized solutions according to the specific needs of customers to ensure that polyester dryer screen dryer belt is perfectly matched with the customer's application scenarios and improve the use efficiency.

FAQ:

Q: What is the temperature resistance range of polyester dryer screen dryer belt?

A: Polyester dryer screen dryer belt can usually withstand a temperature range of -40°C to +150°C. The specific temperature resistance depends on the polyester material used and the process treatment method.

Q: Is the polyester dryer screen dryer belt resistant to hydrolysis and chemical corrosion?

A: Yes, the polyester dryer screen dryer belt connected by hydrolysis-resistant polyester spiral ring can effectively resist hydrolysis, and has strong corrosion resistance to weak acids, weak alkalis and general chemicals, and is suitable for humid environments or chemical industries.

Q: How flexible is the polyester dryer screen dryer belt?

A: The radial line of the polyester dryer screen dryer belt is soft and resistant to twists and turns, which can adapt to various conveying equipment to avoid damage caused by excessive bending. At the same time, the weft is straight and wide to maintain the stability of the conveying process.

Q: How long is the service life of the polyester dryer woven mesh screen?

A: The service life depends on the specific use environment and load conditions. Due to its wear resistance, high temperature resistance and moisture resistance, it can usually operate stably for a long time and has a longer service life than traditional conveyor belts.

Q: In which industries are polyester dryer woven mesh screens mainly used?

A: It is suitable for food processing (drying, cooling, cleaning), textile printing and dyeing (cloth conveying), papermaking (paper drying and conveying), wood processing and chemical industries, etc., and can meet the conveying needs of different production processes.

About us:

Shenyang Shuguang pays attention to environmental protection and sustainable development, and actively promotes green production processes. Our polyester vacuum paving belt has achieved remarkable results in medium-density fiberboard production lines. With its excellent chemical resistance and hydrolysis resistance, it helps customers improve production efficiency while meeting the industry's strict requirements for environmental protection and energy saving.