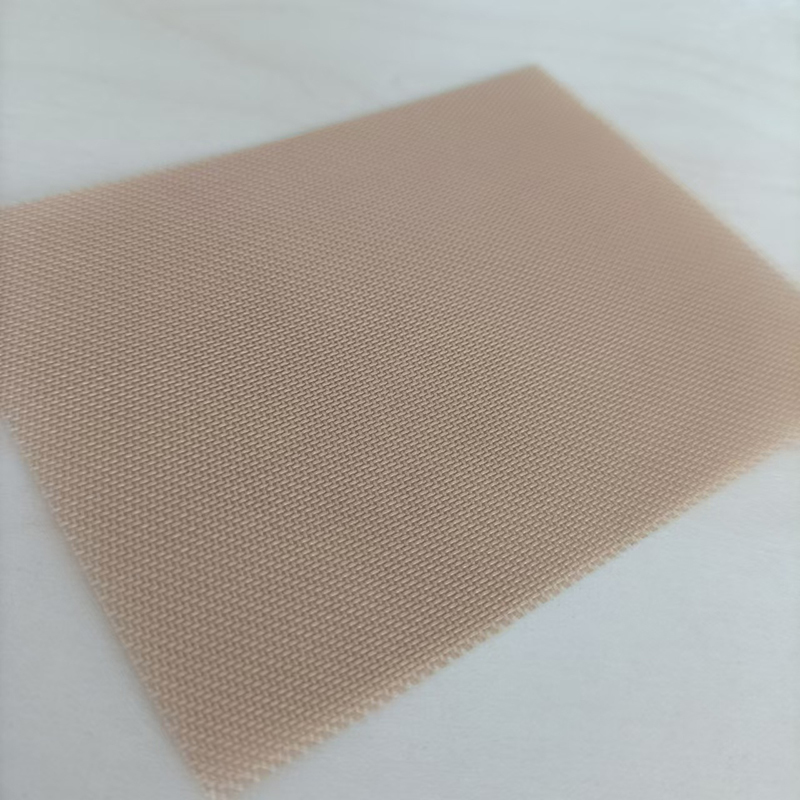

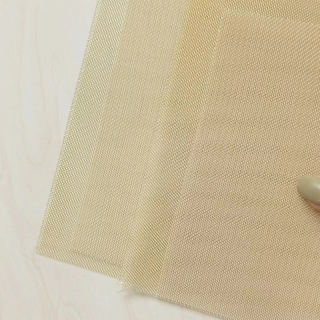

Transformer Board PPS Mesh

1. The 80um Thickness 40 Mesh PPS Mesh we produce has good high temperature resistance and remains stable at 230℃ without affecting performance.

2. The Chemical Resistance Polyphenylene Sulfide PPS Mesh we produce has a smooth surface and reduces residue, which can improve the electrical performance of the insulation board and improve production efficiency.

3. The High Temperature Resistance Polyphenylene Sulfide PPS Mesh we produce is not easy to deform and is suitable for high-voltage environments.

Product introduction:

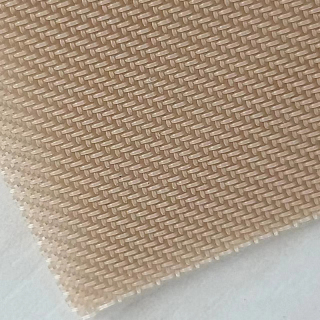

High temperature resistance polyphenylene sulfide pps mesh produced by Shuguang is a non-metallic exhaust net made of high-performance PPS (polyphenylene sulfide) fiber, specially designed for transformer insulation board press. 80um Thickness 40 Mesh PPS Mesh has a smooth surface, high temperature resistance and corrosion resistance, which can effectively reduce metal residue, improve exhaust efficiency and ensure the electrical performance of the insulation board. 80um Thickness 40 Mesh PPS Mesh is widely used in transformer insulation board production, electronic manufacturing, filtration equipment and other industries, providing more efficient and stable solutions for the industry.

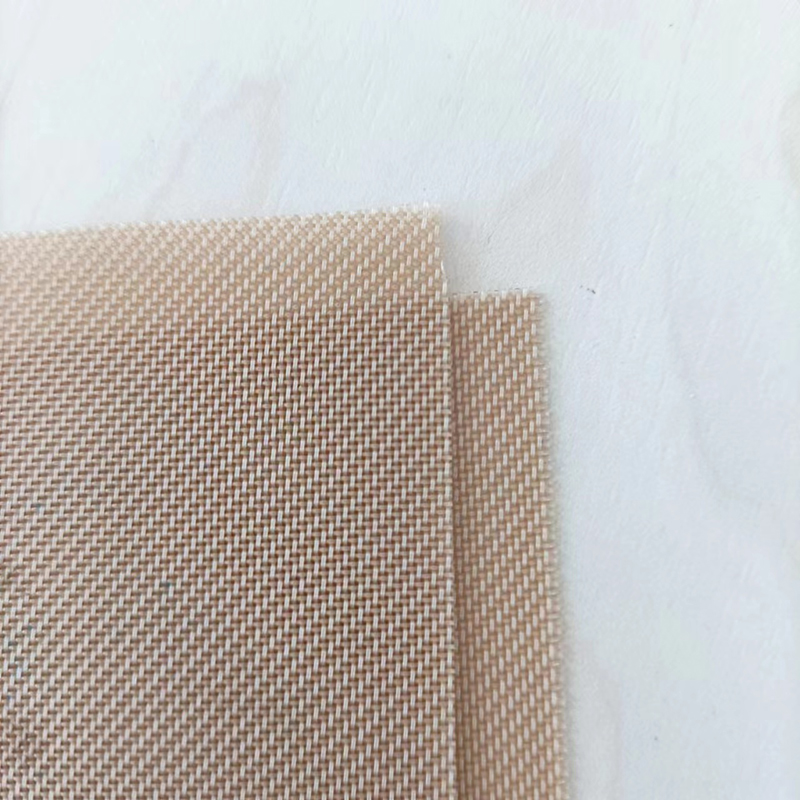

Product advantages of 80um Thickness 40 Mesh PPS Mesh:

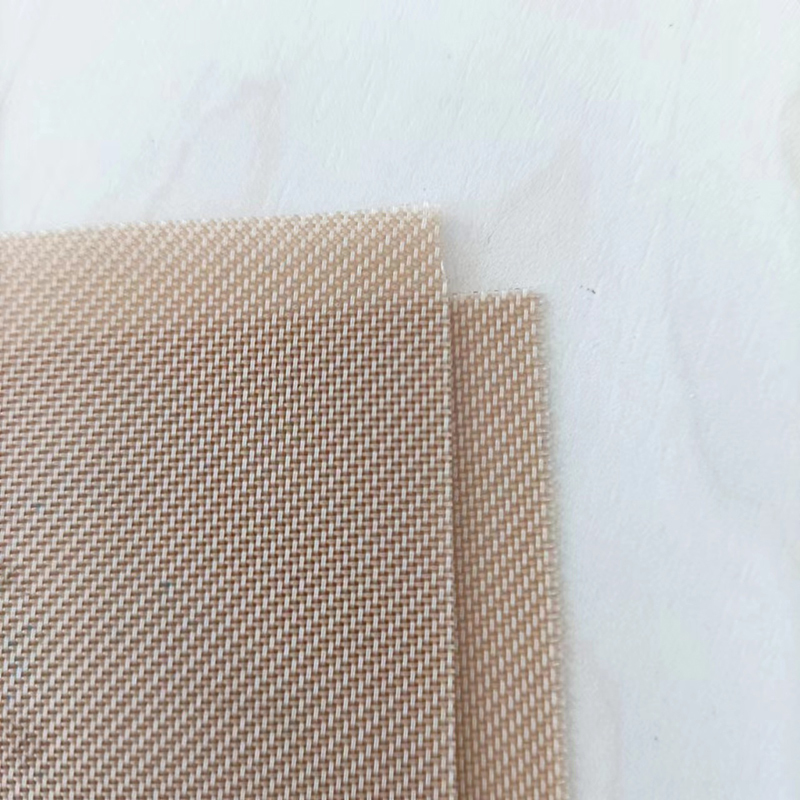

High temperature resistance polyphenylene sulfide pps mesh has excellent high temperature resistance, can withstand up to 230℃, can maintain a stable structure in extreme temperature environments, and is not easy to deform or melt. The PPS material used in 80um Thickness 40 Mesh PPS Mesh has good corrosion resistance and can maintain long-term use even in strong acid and alkali environments without affecting its function. High temperature resistance polyphenylene sulfide pps mesh's high tensile strength enables it to maintain integrity under high pressure environments, is not easy to break or damage, extends its service life, improves production efficiency, and reduces maintenance costs, becoming an indispensable and important material in the manufacturing process of transformer insulation boards.

Product application:

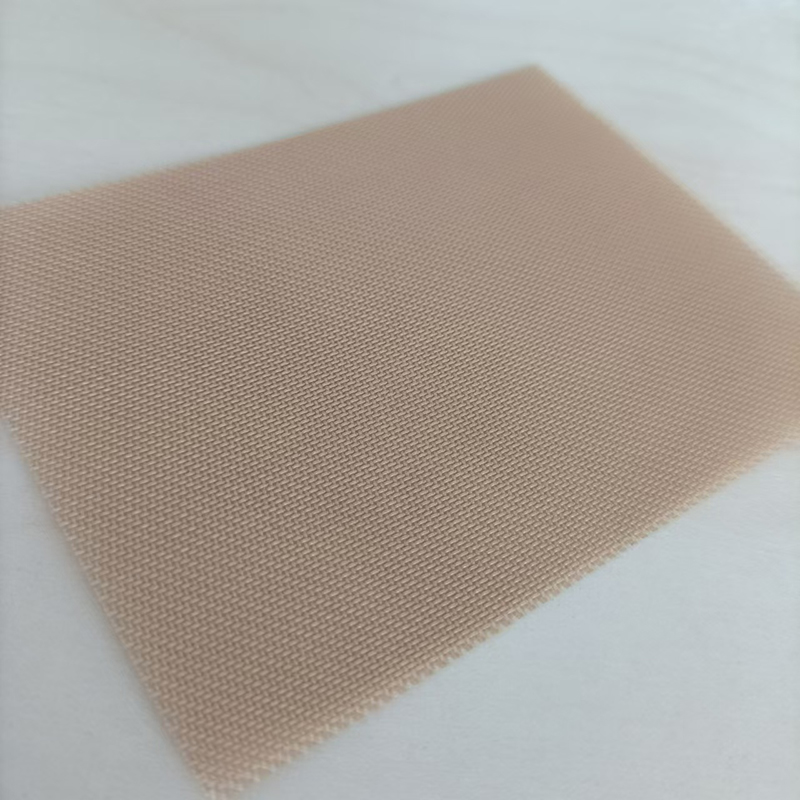

Chemical resistance polyphenylene sulfide pps mesh produced by Shuguang is widely used in the production process of transformer insulation boards, mainly for exhaust and filtration of high-voltage insulation materials. The smooth surface of chemical resistance polyphenylene sulfide pps mesh effectively prevents adhesion and improves the quality of finished products, while reducing metal residues and ensuring the stability of insulation performance. High temperature resistance polyphenylene sulfide pps mesh is also suitable for high-temperature filter press equipment, electronic component manufacturing, chemical filtration, and other filtration and support materials in high-temperature corrosion-resistant environments. Chemical resistance polyphenylene sulfide pps mesh is widely used in many industries such as electricity, electronics, aerospace, etc., providing reliable support for high-precision manufacturing.

How to store chemical resistance polyphenylene sulfide pps mesh?

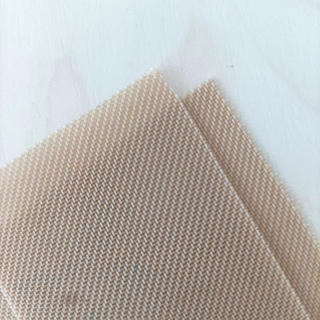

80um Thickness 40 Mesh PPS Mesh should be stored in a dry, ventilated environment, away from moisture and direct sunlight to prevent material aging and performance degradation. The optimal storage temperature is 5℃~30℃, and the relative humidity is less than 60%. 80um Thickness 40 Mesh PPS Mesh should be placed flat or rolled to avoid folding and squeezing to maintain structural integrity. 80um Thickness 40 Mesh PPS Mesh can be covered with dustproof cloth or plastic film to prevent dust and pollution, ensuring that 80um Thickness 40 Mesh PPS Mesh can still maintain excellent filtration performance and mechanical strength after long-term storage.

Customer reviews:

Our 80um Thickness 40 Mesh PPS Mesh has been highly praised by many customers for its excellent high temperature resistance and excellent exhaust effect. Transformer manufacturers said that chemical resistance polyphenylene sulfide pps mesh can maintain a stable shape in high temperature environments, ensuring efficient production of insulation boards; electronic equipment companies reported that the smooth surface of 80um Thickness 40 Mesh PPS Mesh greatly reduced metal residue and improved product quality; filter equipment suppliers also recognized the corrosion resistance and high tensile strength of chemical resistance polyphenylene sulfide pps mesh, and that it can still maintain good performance after long-term use. They have repurchased it many times, further proving the reliability and durability of our high temperature resistance polyphenylene sulfide pps mesh.

About us:

Shenyang Shuguang, as an industry leader with a history of more than 60 years, focuses on the research and development and production of high-performance woven mesh. Our stainless steel wire mesh, conductive conveyor belt and other products have been widely used in transformer, power, chemical and other industries. Through technological innovation and efficient production processes, we are able to provide customers with high-quality and customized solutions to help them improve production efficiency and product quality.