Quality Assurance

Quality assurance is the core principle we always adhere to. Starting from the procurement of raw materials, we strictly control the quality, select high-quality stainless steel and polyester materials, and conduct multiple rounds of rigorous testing to ensure that each batch of raw materials meets international standards. Only raw materials that have passed the inspection will enter the production link, laying a solid foundation for the stability of subsequent processes and product quality.

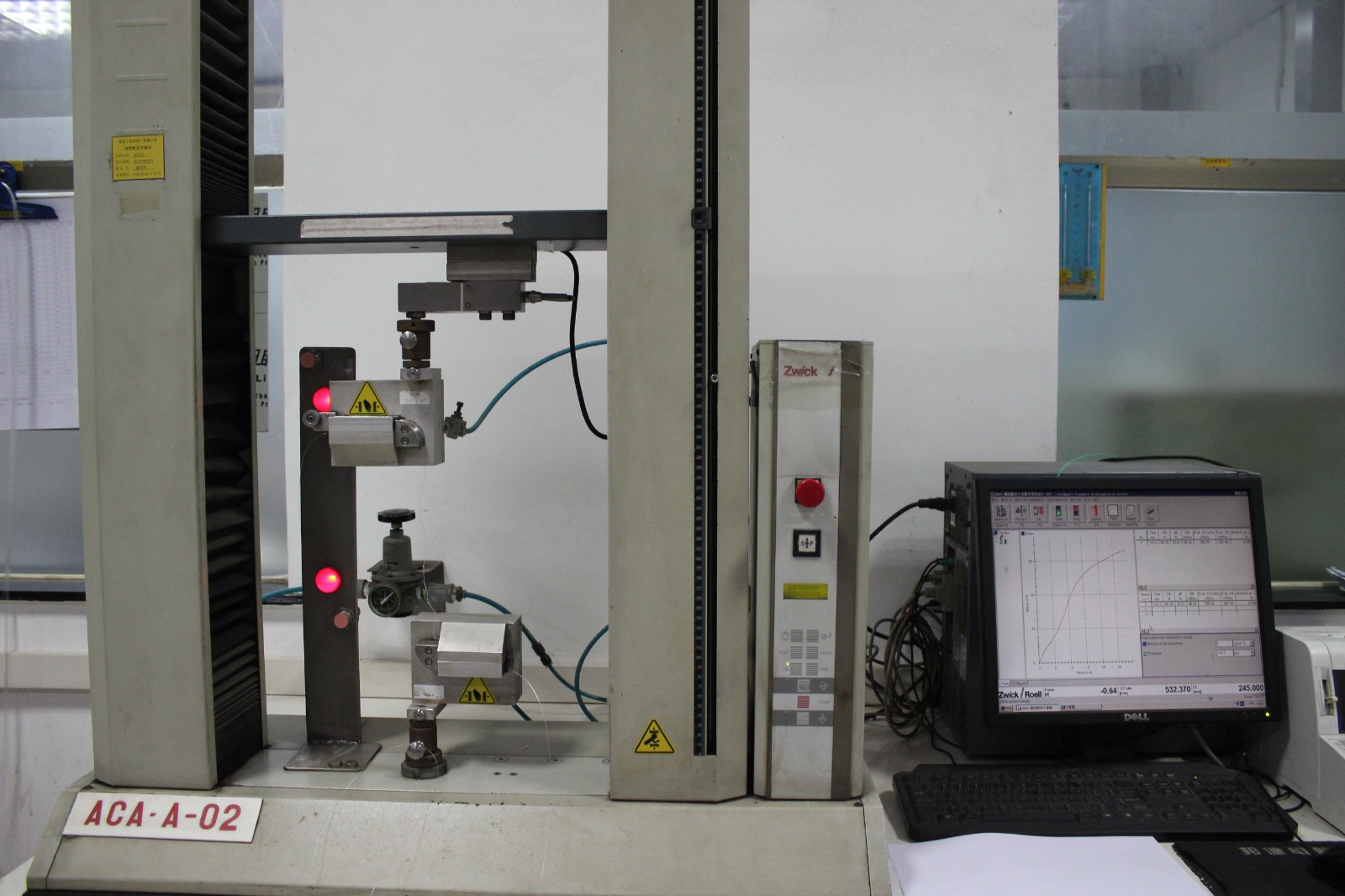

During the production process, we use advanced process technology and are equipped with experienced professionals to strictly monitor each process. From wire stretching, weaving to molding, each link meets the requirements of the international quality standard system to ensure the consistency and stability of the product. In addition, we have also introduced intelligent testing equipment to further improve production accuracy, reduce errors, and improve the quality of finished products.

In the end, all finished products will be strictly tested by precision instruments, including strength testing, durability testing, etc., to ensure that product performance fully meets the standards. Only products that have been screened layer by layer and meet quality requirements will enter the market to ensure that every net received by customers has excellent quality and reliable service life.