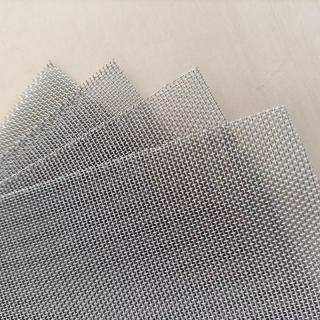

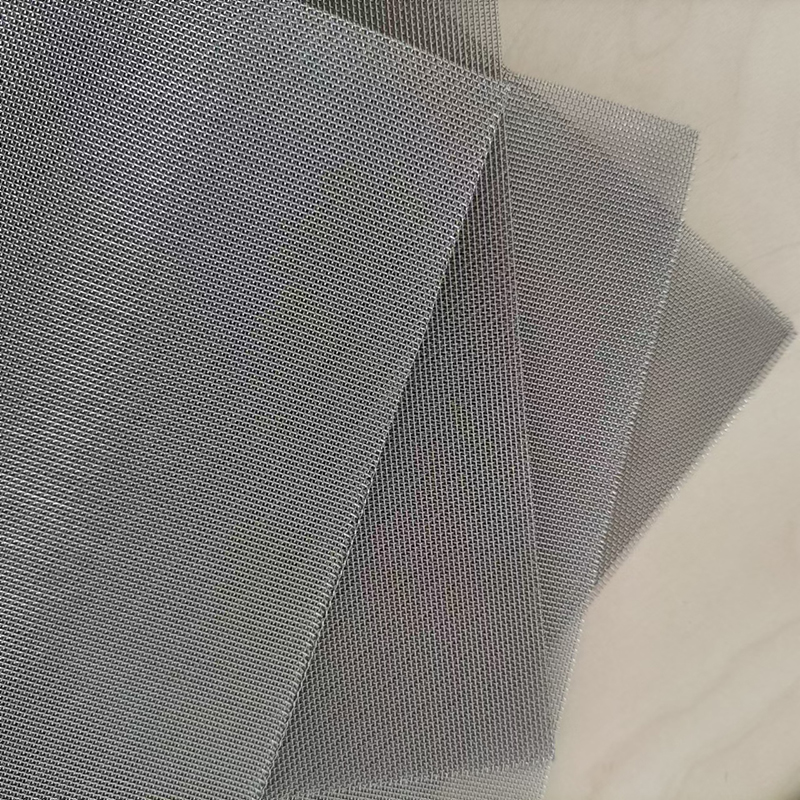

304L Stainless Steel Mesh

1. Each wire of the 304 Stainless Steel Woven Metal Mesh we produce is precisely controlled to ensure consistent mesh size, suitable for high-precision applications.

2. The SS 304L Fine Mesh Roll we produce has excellent tensile strength and can be used for a long time without failure.

3. The SS 304L Fine Mesh Roll we produce uses fine surface treatment to facilitate daily cleaning and reduce impurity residue.

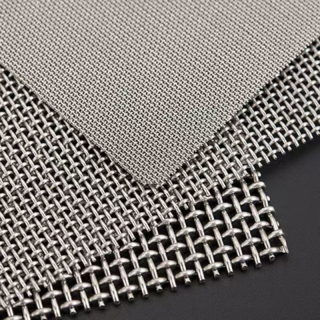

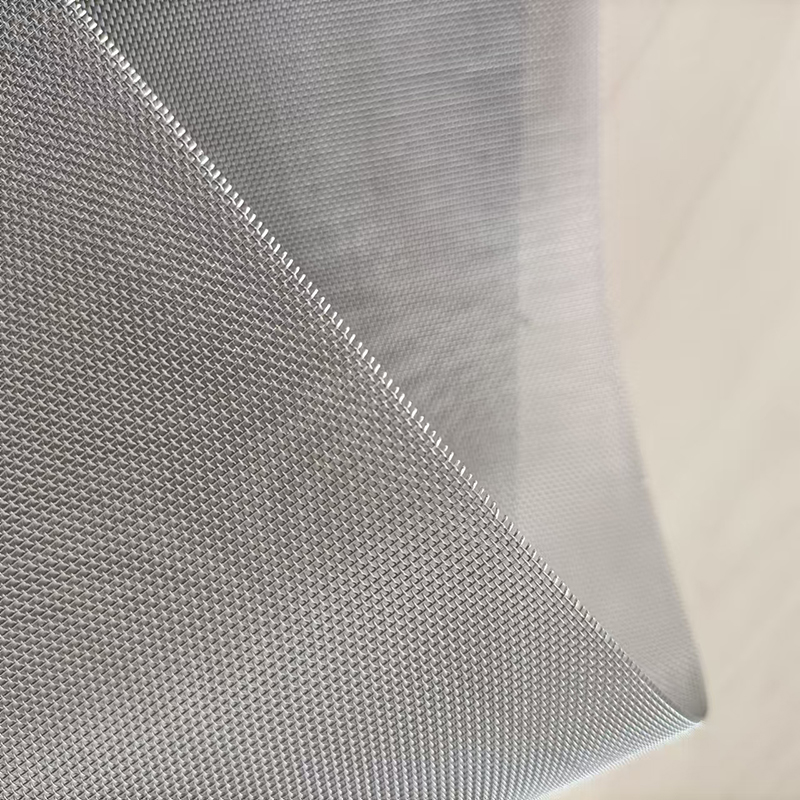

Product introduction of 304/316 stainless steel mesh:

The 304 stainless steel woven metal mesh we produce uses high-end stainless steel wire imported from Japan, which has excellent high temperature resistance and is suitable for screening and filtering work in high temperature environments. 304/316 stainless steel mesh can withstand working temperatures up to 500°C and is widely used in metallurgy, furnace processing, automotive exhaust filtration and other fields.

Product application of 304/316 stainless steel mesh:

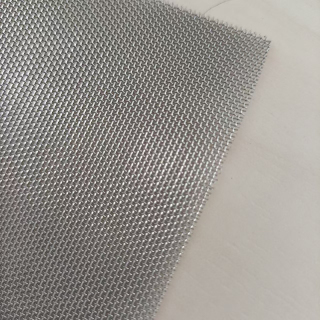

In the construction industry, 304/316 stainless steel mesh is widely used in exterior wall insulation, sound insulation and decoration projects, which not only improves the quality and aesthetics of the building, but also can be used as a building safety net to enhance the overall safety of the building. The petroleum and mining industries rely on the high strength and wear resistance of 304/316 stainless steel mesh, and are used in high-load work such as ore screening, mud filtration and sand control. In the food industry, corrosion resistant 304 stainless steel woven metal mesh relies on hygiene and corrosion resistance to ensure the safety of food processing and storage processes.

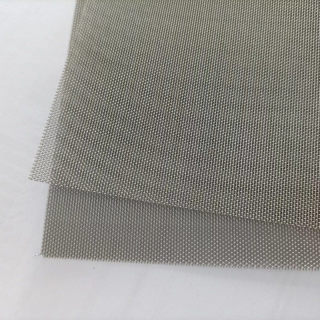

How to clean and maintain it correctly?

During long-term use, the performance of corrosion resistant 304 stainless steel woven metal mesh will be affected by the accumulation of dust, oil or chemical residues. Therefore, regular cleaning and maintenance are the key to ensure its normal use. In general, the surface can be wiped with clean water or neutral detergent to avoid corrosion of stainless steel by acidic or alkaline chemicals. If there are stubborn stains on the corrosion resistant 304 stainless steel woven metal mesh, use a soft brush or ultrasonic cleaner for deep cleaning. In a highly polluted environment, it is recommended to use high-pressure water to rinse the 304/316 stainless steel mesh to ensure the air permeability and filtering effect of the SS 304L fine mesh roll. regularly check the tightness of the fixed parts, and adjust or replace the aging parts in time to extend the service life of the SS 304L fine mesh roll.

FAQs:

Q: How stable is the mesh roll in a high temperature environment?

A: 316 stainless steel mesh can withstand high temperatures of 900℃, and 304 stainless steel mesh can withstand temperatures of 800℃, which are suitable for high-temperature working environments such as metallurgy and chemical filtration.

Q: What is the difference between the production process of SS 304L fine mesh roll and ordinary wire mesh?

A: SS 304L fine mesh roll is woven or welded with high-strength stainless steel wire and does not require galvanizing or rust-proofing, while wire mesh needs to be galvanized or sprayed for corrosion protection.

Q: How to reduce defects in the production process of SS 304L fine mesh roll?

A: By accurately controlling the drawing tension, optimizing the weaving process, avoiding wire damage, and conducting real-time detection, quality defects such as broken wires and uneven mesh can be reduced.

Customer evaluation:

We are a food processing company. The filtration link has a great impact on product quality. The SS 304L fine mesh roll used before is prone to clogging, affecting production efficiency, and frequent replacement increases production costs. The stainless steel filter provided by Shuguang has uniform pore size, smooth surface, and is not easy to adhere to impurities. It is very convenient to clean, has a stable filtration effect, can effectively separate impurities, and improve product purity. ——Quality management manager of a food processing plant

About us:

Shenyang Shuguang always adheres to customer demand-oriented, strengthens internal innovation mechanisms, and provides a variety of products suitable for high temperature and corrosive environments. Our polyester vacuum paving belt has achieved remarkable results in medium density fiberboard production lines and composite material manufacturing by optimizing material formula, and has been favored by many internationally renowned manufacturers and has become a key equipment in their production lines.