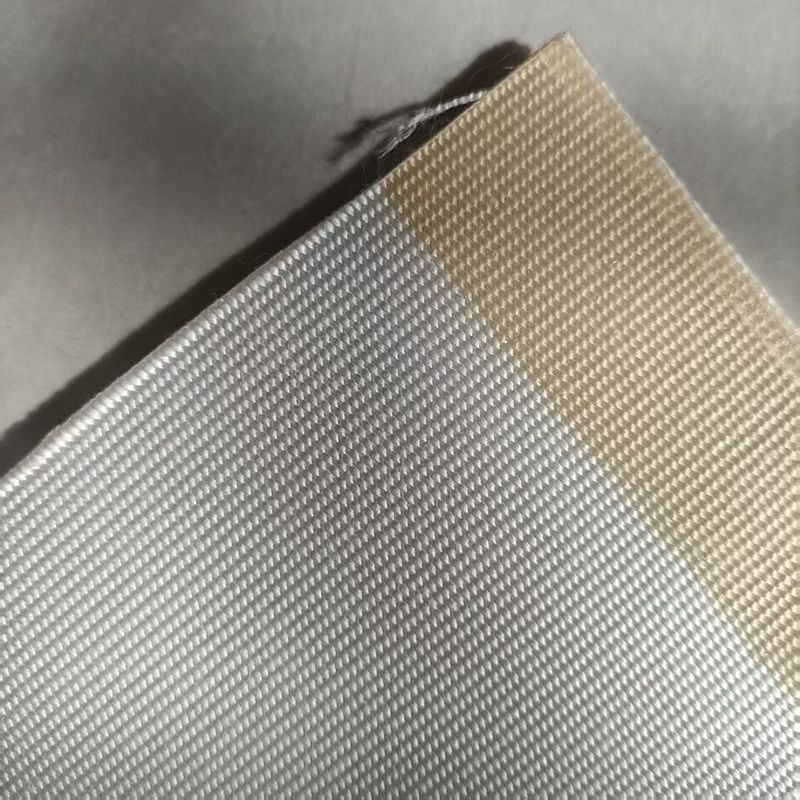

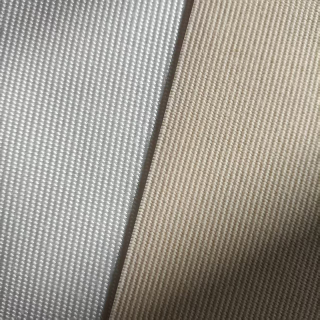

Aramid Flame Retardant Mesh

1. The PTFE Kevlar/Aramid Mesh F305 we produce is made of aramid + PPS + PEEK composite material, which is more resistant to high temperatures.

2. The surface of PTFE Kevlar/Aramid Mesh F305 is smooth and non-adhesive, which improves production efficiency.

3. PTFE Kevlar/Aramid Mesh F305 is made of high-quality wear-resistant materials and is not easily damaged after long-term use.

Product introduction of PTFE Kevlar/Aramid Mesh F305:

The 200 GSM 1313 1414 Meta PARA Aramid Fiber we produce is a high-performance filter material made of aramid fiber yarn, with excellent high temperature resistance, flame retardant, acid and alkali resistance and wear resistance. In order to improve product performance, we upgraded the material of PTFE kevlar/aramid mesh f305, combining aramid with polyphenylene sulfide) and PEEK (polyetheretherketone), so that PTFE Kevlar/Aramid Mesh F305 can be used stably for a long time at higher temperatures, up to 230℃. The high-strength and high-durability materials we use make 200 GSM 1313 1414 Meta PARA Aramid Fiber widely used in harsh industrial environments such as high temperature and strong corrosion, meeting the filtering needs of different fields.

Product advantages of 200 GSM 1313 1414 Meta PARA Aramid Fiber:

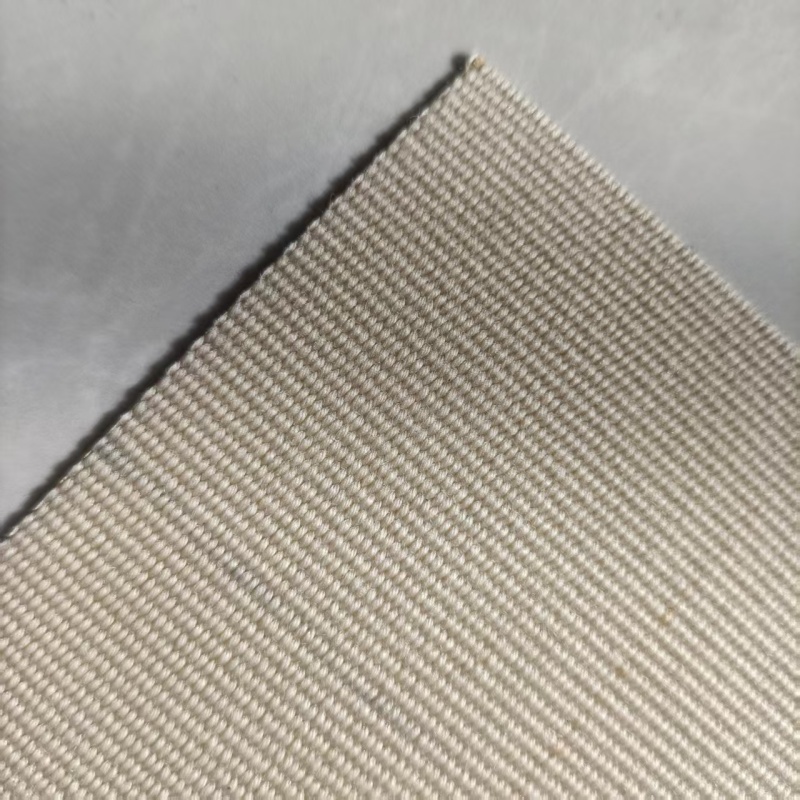

The 200 GSM 1313 1414 Meta PARA Aramid Fiber we produce has good heat resistance, high mechanical strength and chemical stability, far exceeding ordinary filter materials. High temperature resistance is a highlight, and it can be used for a long time in a high temperature environment of 230℃ without deformation or aging due to thermal expansion and contraction. 200 GSM 1313 1414 Meta PARA Aramid Fiber itself has extremely strong flame retardancy and will not support combustion or melt, making it safer in industrial high temperature environments. The chemical corrosion resistance of the 1500D Kevlar 1414 Cloth 220g Aramid Plain Weave we produce can cope with complex working conditions such as acid, alkali, oil pollution, etc., and is particularly suitable for metallurgy, chemical industry and power industry. At the same time, the high-strength and wear-resistant material enables it to maintain stable performance after long-term use, greatly improving service life and work efficiency.

Product application of 1500D Kevlar 1414 Cloth 220g Aramid Plain Weave:

The 1500D Kevlar 1414 Cloth 220g Aramid Plain Weavewe produce is widely used in many fields such as high-temperature filtration, industrial dust removal, thermal protection equipment, etc., especially suitable for:

1. High-temperature gas filtration in metallurgy, steel, and power industries.

2. Corrosion-resistant filtration in chemical, pharmaceutical and other industries.

3. High-strength protective materials in high-end technology fields such as aerospace and military industry.

4. High-temperature flame-retardant layer for firefighting and special protective clothing.

Product Instructions of 1500D Kevlar 1414 Cloth 220g Aramid Plain Weave:

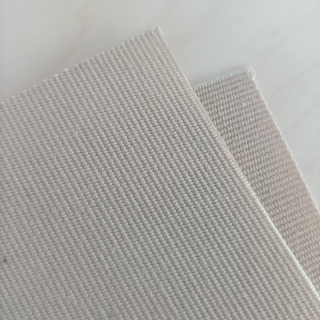

During storage, aramid kevlar cloth weaving mesh should be kept in a dry and ventilated environment, away from moisture and direct sunlight to ensure its long-term stability. When in use, aramid kevlar cloth weaving mesh can be cut and installed according to the needs of the equipment to ensure that the size is suitable to achieve the best filtering effect. When cleaning aramid kevlar cloth weaving mesh daily, it is recommended to use a mild detergent and avoid using strong acid and alkali liquids to extend the service life. At the same time, aramid kevlar cloth weaving mesh should be avoided from contact with sharp metal objects to prevent scratching the mesh surface and affecting the use effect.

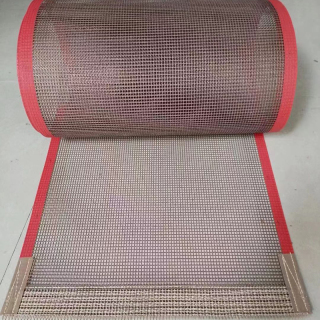

Packaging and delivery of Aramid Kevlar Cloth Weaving mesh:

We use pressure-resistant and moisture-proof packaging bags for packaging to ensure that aramid kevlar cloth weaving mesh is not damaged during transportation and to maintain the integrity of the product to the greatest extent. According to customer needs, we can provide packaging of different specifications and support customized packaging solutions to meet the needs of different purchase quantities. The delivery methods cover domestic and foreign express delivery, logistics transportation, and support expedited delivery services to ensure that customers can quickly receive the required PTFE Kevlar/Aramid Mesh F305 and improve work efficiency.

Customer evaluation:

Many customers have given high praise after using our PTFE Kevlar/Aramid Mesh F305 for a long time. Mr. Wang, the head of an industrial filtration manufacturer, said that after their equipment used our 1500D Kevlar 1414 Cloth 220g Aramid Plain Weave, the filtration effect was significantly improved and the equipment maintenance cost was greatly reduced. Ms. Li, a purchasing manager in the chemical industry, praised Shuguang's PTFE Kevlar/Aramid Mesh F305 for its stable performance in acid and alkali environments, which is far superior to ordinary filters. These feedbacks prove the reliability and high performance of our Aramid Kevlar Cloth Weaving mesh in practical applications.

Product parameters:

| Weaving method: | plain weave |

| Warp: | Metas 1313 |

| Weft: | Kevlar 1414 |

| Mesh specifications: | 1×1, 4×4, 10×10 or customized |

| Color: | black, brown |

| Temperature tolerance range: | up to 230℃ |

About us:

Shenyang Shuguang was established more than 60 years ago and focuses on the research and development and production of stainless steel wire mesh, polyester filter belt and other products. Our products are widely used in many fields such as electricity, chemical industry, food, etc., especially in transformer production and chemical filtration. Relying on internationally leading technology and exquisite craftsmanship, we provide customers with customized solutions to ensure the stability and reliability of products in high-intensity and complex environments. We are committed to promoting industry development with innovation and always standing at the forefront of the industry.