- Home

- >

- Products

- >

- Teflon Mesh Belt

- >

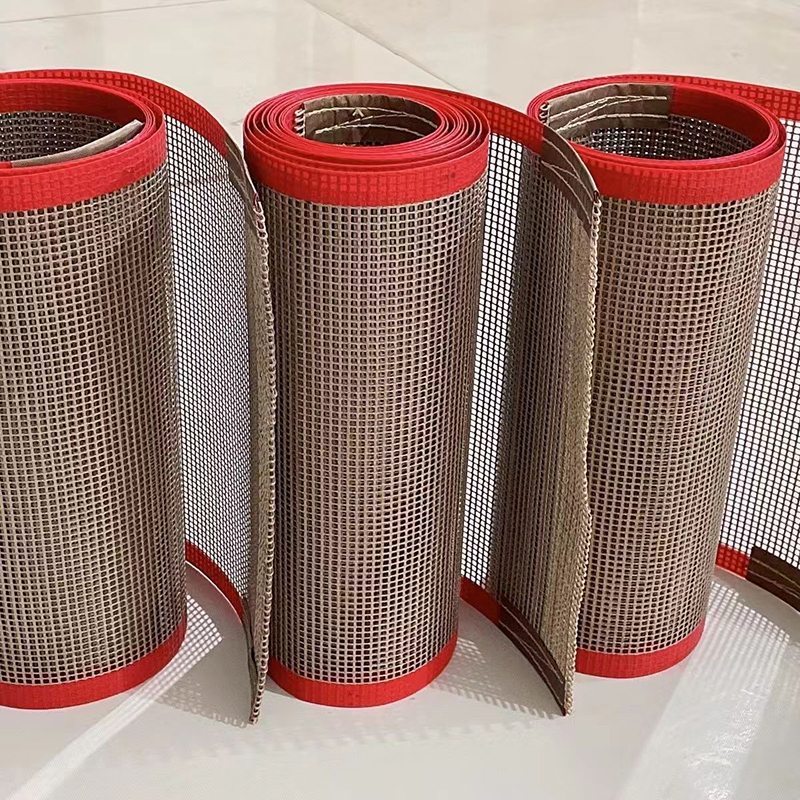

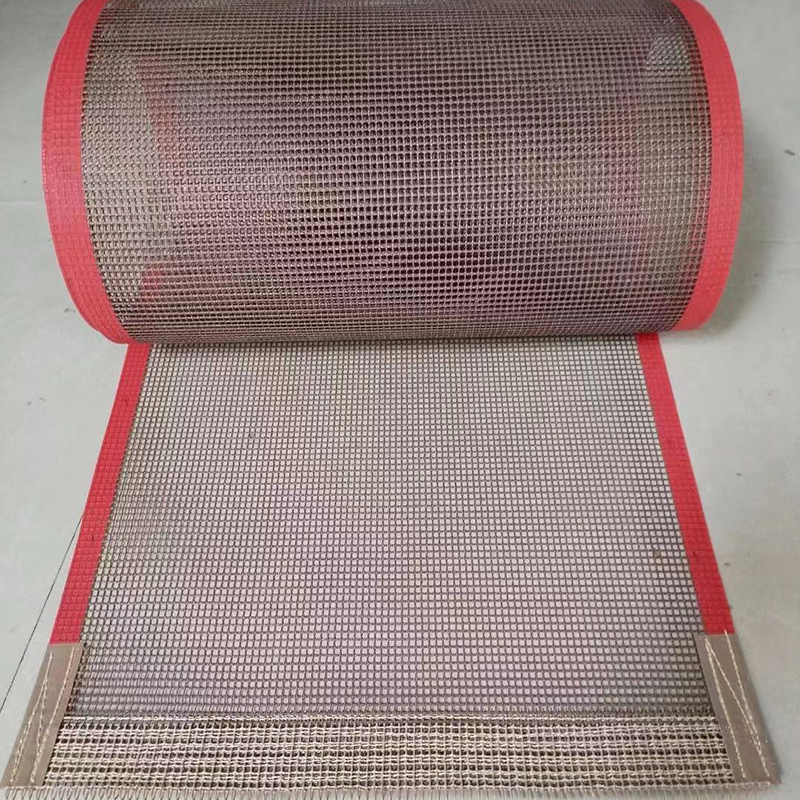

Teflon Mesh Belt

1. The PTFE Mesh Belts we produce can operate stably in an environment of -70℃ to +260℃.

2. The surface of the PTFE Mesh Belts we produce is smooth and does not adhere to materials, reducing downtime for maintenance.

3. The PTFE Mesh Belts we produce is suitable for drying and curing processes that require hot air circulation to improve thermal efficiency.

Product introduction of teflon conveyor mesh belt:

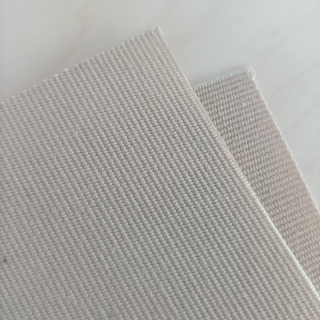

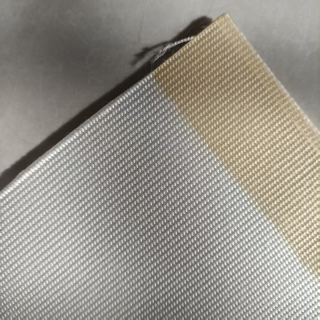

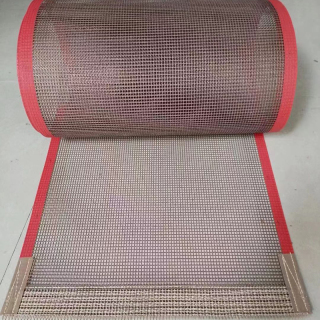

The Teflon conveyor mesh belt we produce uses high-quality glass fiber base cloth and is coated with high-quality polytetrafluoroethylene (PTFE), giving it excellent properties such as high temperature resistance, corrosion resistance, bending resistance, high air permeability, and strong anti-stickiness. Teflon conveyor mesh belt is suitable for continuous conveying operations in high temperature environments, is not easy to deform, and has a long service life. We provide a variety of Teflon conveyor mesh belt hemming styles and joint specifications, which can be widely used in food processing, electronic manufacturing, printing and packaging, textile drying, plastic curing and other industries to meet different production needs.

Product advantages of Teflon conveyor mesh belt:

The Non-Stick Teflon Mesh Belt we produce can be used for a long time in the temperature range of -70℃ to +260℃ with its excellent heat resistance stability, and is not easy to age or deform. The anti-stick properties of Non-Stick Teflon Mesh Belt and PTFE Mesh Beltsprevent materials from adhering to the surface of the mesh belt, reducing cleaning and maintenance costs and improving production efficiency. Non-Stick Teflon Mesh Belt has extremely high corrosion resistance and can resist most chemical reagents, solvents and oil stains, making it suitable for complex industrial environments.

Product application of Non-Stick Teflon Mesh Belt:

The Non-Stick Teflon Mesh Belt we produce is widely used in food processing (such as baking, freezing, cooking), printing and packaging (such as UV curing, screen printing drying), textile printing and dyeing (such as fabric shaping, drying), electronic manufacturing (such as PCB board conveying, curing), rubber plastics (such as plastic welding, leather embossing) and other fields. The breathable structure of Teflon mesh conveyor belt is suitable for production processes that require uniform heating, improving efficiency and ensuring product quality.

Product instructions of Teflon Mesh Conveyor Belt:

During the installation and use of Teflon mesh conveyor belt and PTFE Mesh Belts, ensure that the Teflon mesh conveyor belt is properly tensioned to prevent it from being too loose or too tight to affect the transmission effect. Avoid scratches with sharp objects or squeezing with heavy objects to extend the life of Teflon mesh conveyor belt. It is recommended to clean the PTFE Mesh Belts regularly after using it to clean the residual oil or materials on the surface to maintain its good anti-stick and breathable properties.

Product specifications and dimensions of PTFE Mesh Belts:

| Product name: | PTFE Mesh Belts |

| Material: | Glass fiber + Teflon coating |

| Temperature range: | -70℃ to +260℃ |

| Breathability: | Highly breathable design, suitable for hot air circulation equipment |

| Edge style: | Different types of edging can be selected to meet various conveying needs |

| Mesh size: | 1×1mm, 4×4mm, 10×10mm or customized |

| Connector type: | Various specifications can be selected to adapt to different equipment |

About us:

Shenyang Shuguang was established more than 60 years ago and focuses on the research and development and production of high-performance PTFE Mesh Belts products. The company's products include stainless steel wire mesh, conductive conveyor belts, etc., which are widely used in transformers, power, chemical and other industries. Through continuous technological innovation and optimization, we continue to improve product performance and strive to provide customers with efficient, high-quality customized solutions to help them achieve higher production efficiency and product quality.