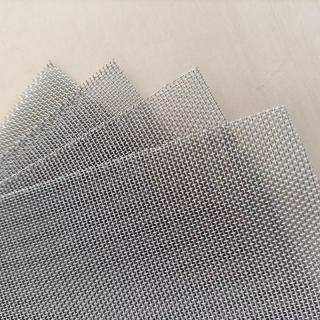

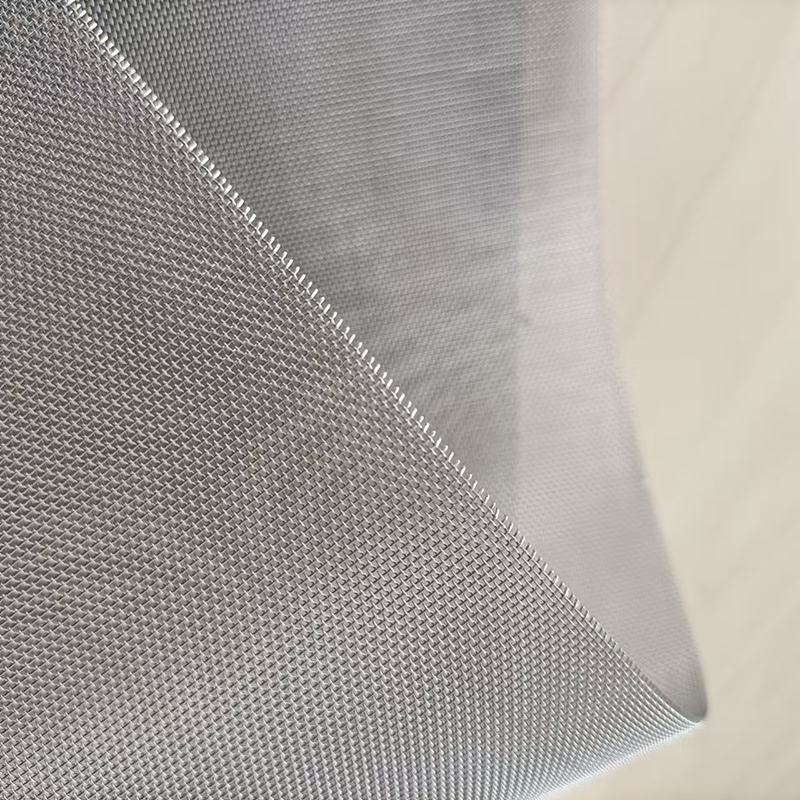

Stainless Steel Woven Mesh

1. The stainless steel wire mesh we produce is stronger and can work continuously and stably under complex conditions.

2. The surface treatment of the Woven SS 304 Wire Mesh we produce is smooth, no additional treatment is required, and it is more worry-free to use.

3. The Durable Woven Wire Mesh we produce is made of high-quality stainless steel imported from Japan, which has strong corrosion resistance and remains stable in corrosive environments.

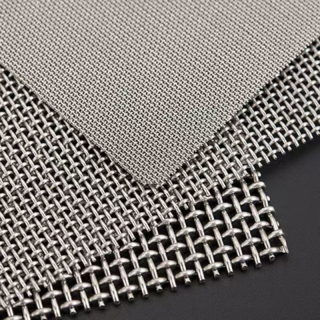

Product Introduction of SS 316 woven mesh sheet:

The SS 316 woven mesh sheet we produce not only has excellent durability, but also because SS 316 woven mesh sheet uses high-quality stainless steel imported from Japan, it is not easy to wear out during long-term use and has a high cost-effectiveness. Durable woven wire mesh is a long-term investment, reducing the cost of frequent replacement and maintenance.

Product Advantages of SS 316 woven mesh sheet:

Our SS 316 woven mesh sheet uses 316L stainless steel wire imported from Japan. After fine surface treatment, the surface of SS 316 woven mesh sheet is smoother and less likely to accumulate impurities. Whether in fields with high hygiene requirements such as medicine and food processing, smooth surface treatment can effectively reduce the difficulty of cleaning and ensure that SS 316 woven mesh sheet meets hygiene standards. Japan's advanced technology allows our SS 316 woven mesh sheet to maintain excellent performance in environments with extremely high hygiene requirements.

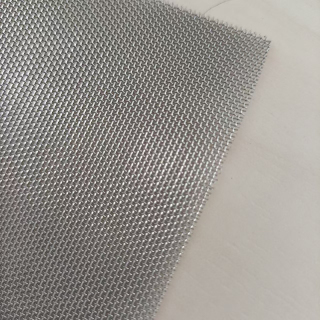

Product application of woven ss 304 wire mesh:

In the electronics and optoelectronics industries, woven ss 304 wire mesh is widely used in the production of precision products such as printed circuit boards and membrane switches due to its high precision and low elongation. In the food industry, woven ss 304 wire mesh's corrosion resistance and good hygiene ensure the safety of food processing, storage and transportation. In the mining industry, woven ss 304 wire mesh helps improve the efficiency of ore mining during ore screening and grading with its high strength, wear resistance and high temperature resistance.

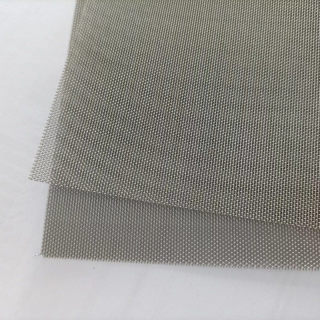

Why choose our durable woven wire mesh?

The woven ss 304 wire mesh we produce uses high-quality stainless steel wire raw materials from Japan and strict production standards. We use a complete testing process and advanced testing equipment to ensure that each batch of woven ss 304 wire mesh meets the international market's requirements for accuracy, strength and corrosion resistance. Thanks to this high standard of quality control, our woven ss 304 wire mesh has been widely recognized and praised worldwide.

Specification List of Durable Woven Wire Mesh | |||||

| Mesh/lnch (mesh) | Wire Diameter(mm) | APerture | Mesh/lnch (mesh) | Wire Diameter(mm) | APerture |

2 | 1.8 | 10.9 | 60 | 0.15 | 0.273 |

3 | 1.6 | 6.866 | 70 | 0.14 | 0.233 |

4 | 1.2 | 5.15 | 80 | 0.12 | 0.198 |

5 | 0.91 | 4.17 | 90 | 0.11 | 0.172 |

6 | 0.8 | 3.433 | 100 | 0.1 | 0.154 |

8 | 0.6 | 2.575 | 120 | 0.08 | 0.132 |

10 | 0.55 | 1.99 | 140 | 0.07 | 0.111 |

12 | 0.5 | 1.616 | 150 | 0.065 | 0.104 |

14 | 0.45 | 1.362 | 160 | 0.065 | 0.094 |

16 | 0.4 | 1.188 | 180 | 0.053 | 0.088 |

18 | 0.35 | 1.06 | 200 | 0.053 | 0.074 |

20 | 0.3 | 0.97 | 250 | 0.04 | 0.061 |

26 | 0.28 | 0.696 | 300 | 0.035 | 0.049 |

30 | 0.25 | 0.596 | 325 | 0.03 | 0.048 |

40 | 0.21 | 0.425 | 350 | 0.03 | 0.042 |

50 | 0.19 | 0.318 | 500 | 0.025 | 0.0385 |

Cutting and processing methods of durable woven wire mesh:

In practical applications, it may be necessary to cut and process durable woven wire mesh according to specific needs. When cutting, it is recommended to use professional tools such as mesh cutters, plasma cutters or laser cutters to ensure neat cutting edges and reduce burrs. For thicker durable woven wire mesh, you can mark the cutting area first and cut it step by step to avoid mesh deformation or material damage due to excessive force. After cutting, it is recommended to use sandpaper or a grinder to polish the edges to remove sharp parts and improve safety. At the same time, the processed durable woven wire mesh should be cleaned in time to prevent metal debris from affecting subsequent use.

FAQs:

Q: What are the applications of stainless steel mesh in the chemical industry?

A: Since stainless steel mesh is resistant to acid and alkali and corrosion, it is widely used in filtration, separation, catalyst support, gas-liquid separation and protective covers in chemical plants, especially 316L stainless steel mesh is suitable for strong corrosive environments.

Q: What are the advantages of stainless steel mesh compared with galvanized wire mesh?

A: Stainless steel mesh is more corrosion-resistant and has a longer service life. It is suitable for humid, high-temperature, acid-base environments. Although galvanized wire mesh is cheaper, it may rust and the coating will fall off after long-term use. It is suitable for short-term or general environment use.

Q: What is the production process of stainless steel mesh?

A: The production process includes material selection (such as 304, 316L stainless steel wire), wire drawing, weaving (plain, twill, mat type, etc.), cutting, welding (such as frame reinforcement), surface treatment (pickling, passivation, polishing), testing and packaging.

About us:

Shenyang Shuguang was established more than 60 years ago and is committed to the research and development and production of high-performance woven mesh products such as stainless steel wire mesh and conductive conveyor belts. We use internationally leading production technology and a rigorous quality management system to ensure that each product meets high standards and customer needs. Whether it is transformer production in the power field, filtration and separation in the chemical industry, or production and transportation in the food industry, our products have brought significant production benefits to customers with their stable performance and durability.